Specially Designed for Blown Film Extrusion

Pivoting of electrode bar on impact of thickening of films

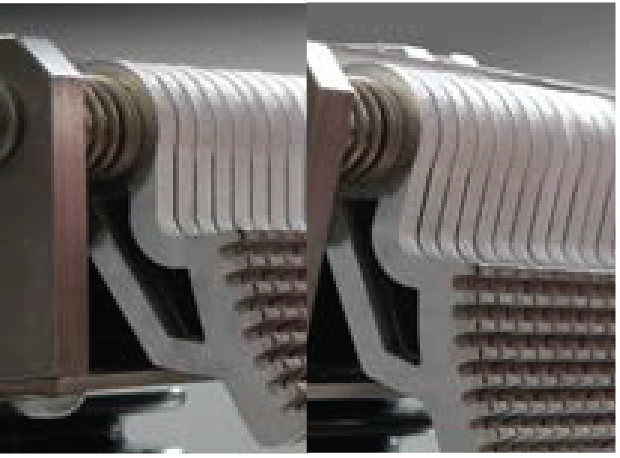

Millimeter scale for easy and precise adjusment of treatment areas.

Long live and operating time due to use of robust parts.

Easy and precise adjusment of segments

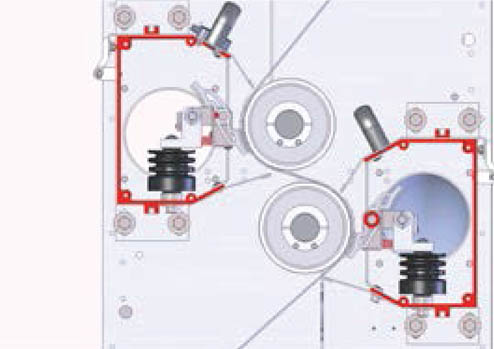

Effective, Compact and Easy to Use

Operating Postion

Standby Postion

Services Postion

Technical Details

- Two-sided treatment

- Working width up to 3500 mm

- Line speed up to 200 m/min

- Discharge gap 2 mm

- Segment type electrodes made of aluminium

- Segment width 5 or 10 mm

- 8 or 10 discharge lines per segment

- Pneumatic movement of treatment roll

- Spring loaded electrode bar

- Power control adjusting to line speed

- Speed-dependent start/stop control

- Automatic switch-off at opening of electrode housing

- Transformer mounted on the station

Options

- Switchover unit for alternating treatment

- Double power supply for two-sided and alternating treatment

- Stainless steel segments

- Segment-width 2 mm

- Fixed length treatment electrode

Advantages

- Easy feed through of film due to pneumatic movement of treatment roll

- High productivity with the fast and safe adjustment of segments

- Less down time through fast change of treatment roll

- Long live due to use of solid and robust isolation parts in high-voltage areas

- Easy and secure operation by speed-dependent control of power

- Quick optical check through inspection window or by easy opening of housing

- Secure process with pivoting of electrode bar by impact

- High process reliability through effective EMC shielding