Optimum Control of your Flexo Plates and Sleeves

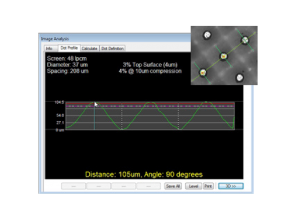

X|Y|Z readings, Screen Count, Percentage, Relief Depth, Compression Simulation, Angles

The FlexoPlate QC Workflow

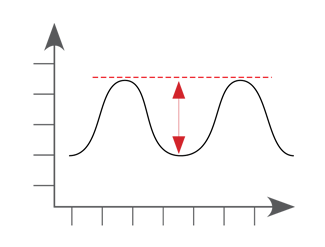

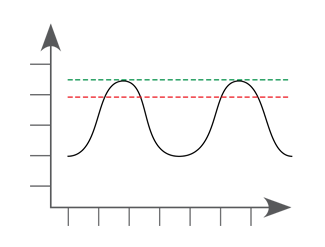

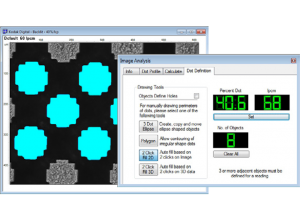

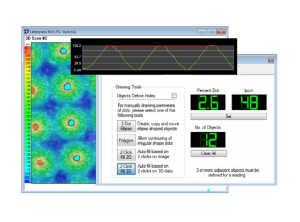

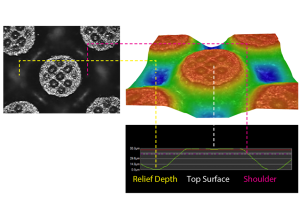

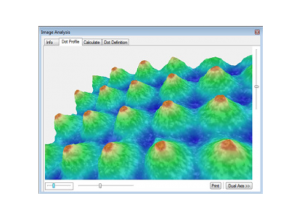

The AniCAM Flexoplate QC Workflow provides two reading methods: 2-dimensional readings with an automatic reflective or translucent dot detection and a 3-dimensional analysis which provides additional information on dot shape, height and relief depths.

Quality Control is Essential

Printers often charge trade-houses for lost productivity if the fault is proven to be theirs – trade houses need to check and maintain their quality to ensure they meet their customers needs.

The time and cost of defective plates will increase waste, reduce productivity and profitability

Cost savings made over time through Quality Control on dot shape, relief depths and dot sizes can be significantly high and will result in a fast Return of Investment.

Any Flexo Plate material and Sleeves – flat or in the round, Direct laser engraved Elastomer plates and sleeves

Halftone dots from 55 to 250 lpi | 22 – 100 lpcm, Accuracy: ± 0.5% over full range of readings, 2D and 3D visual and graphical dot analysis, Geometric measurements.

Dynamic Graphic Display

Screen Angle/Ruling calculation

.fcp format (incl. 2D/3D info); JPEG and BMP (bitmap export)

1 co-axial and 2 x 9 radial white light LEDs (SW-controlled)

USB2.0 Control via PC

External ac power supply (Optional: Battery Pack)

AniCAM Case: 37 x 30 x 17.5 cm (W x D x H)

AniCAM with Case: 5 kg / 11.0 lbs

Humidity: 40% – 60%, non-condensing

Annual Service Contract

WEB-based training and support

X-axis micro adjustment for an exact axial positioning of the camera. (Increases the minimum roll/cylinder diameter to 81mm)

Y-axis micro adjustment for an exact transverse positioning of the camera. (Increases the minimum roll/cylinder diameter to 81mm)